Project Delays Are Killing Your Schedule—Here's Your Fix

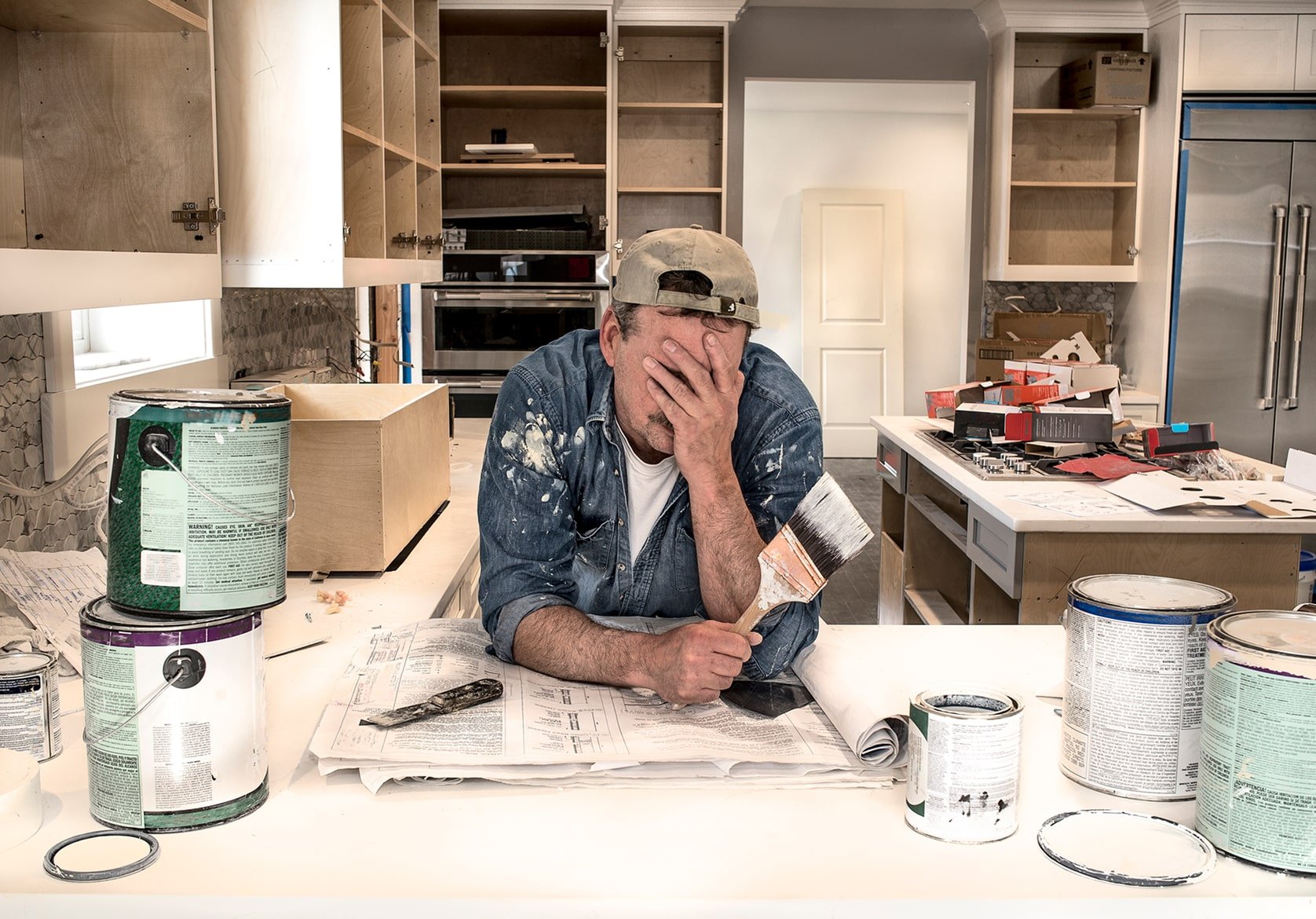

You’re juggling permit delays, rising costs, and anxious clients wondering when their project will actually start. Your subs are booked solid. Material lead times keep shifting. And every time you adjust one timeline, two others get thrown off.

It might seem like everything is conspiring to cause delay after delay. 82% of contractors say material shortages are the biggest cause of delays, so it’s no surprise that the average single-family home now takes 8.3 months to build—up from 7 months before the pandemic.

But some contractors are hitting their timelines while competitors scramble. The difference: Systems that anticipate disruptions before they derail projects.

Why projects stall in today’s market

Four factors are hitting contractors hard—often all at once.

- Permitting is a silent killer. Whitney Hill, co-founder and CEO of SnapADU in San Diego, says permitting is the biggest delay driver. Staffing shortages in permit offices and constantly evolving enforcement around fire requirements slow everything down.

- Supply chains still haven’t recovered. Lead times remain unpredictable. You either order early and tie up cash, or you risk waiting weeks when materials finally get specified.

- Labor shortages affect every trade. 92% of construction firms report difficulty finding qualified workers, and 54% of contractors say shortages have led to delays. When your electrician is booked for three months, your timeline adjusts whether you like it or not.

- Cash flow disruptions amplify everything else. Late payments cause major disruptions—and 76% of contractors lost at least a week of progress due to a delayed payment. Worse, 67% of clients don’t realize payment timing affects construction schedules at all.

Hill manages about 30 ADU projects annually in one of the toughest permitting environments in the country. Her systems keep projects moving even when outside factors threaten timelines. Here’s what’s working:

1. Build contingency planning into your first conversation

Most contractors add buffer time after the first delay hits. Smart ones bake it into their initial estimates.

“We incorporate contingency planning from the outset of a job, using templates based on project size, jurisdiction, and specific nuances like retaining walls,” Hill says. A thorough risk assessment and clearly defined scope of work reduces the likelihood of disputes, change orders, or cost overruns.

What this looks like: Create templates by project size and complexity, including a 5-15% contingency reserve as a visible line item. Map out the likely disruption points, such as permits, inspections, and utility connections, and explain them upfront.

2. Use one scheduling system

Hill’s team relies on BuilderTrend for schedules, purchase orders, and client invoicing. When timelines shift, the system automatically adjusts and notifies relevant trades. But it doesn’t necessarily matter which system you choose, as long as you choose. “Consistent use of a single software across the team, trade partners, and clients is most important,” Hill says.

Specialized project management software streamlines your timeline and helps identify areas where you can trim costs. It also makes sure all of your projects are on the same page—even if they’re on opposite side of the metro.

What this looks like: Choose one platform and require everyone to use it, including employees, subs, and clients, who can have view-only access for transparency. Link schedules to purchase orders so changes cascade automatically.

3. Stage-gate your projects to protect capacity

Taking on too many projects at once overloads subs, burns out your team, and causes every timeline to slip.

Hill manages this by “stage-gating”—kicking off a set number of projects each month to create orderly job releases and prevent overloading subcontractors. For smaller contractors, Hill recommends “having a comprehensive view across all jobs for each phase and setting limits on work in progress.”

Urgent time pressures can compromise good decision-making. You might feel pressured to accept jobs you don’t have capacity for, but sometimes saying no is the smartest play.

What this looks like: Set monthly limits on new starts. Create queues for projects waiting to begin. Maintain a dashboard showing what phase each job is in.

Your script: “We limit how many projects we start each month so your job gets focused attention. You’re in our November start queue—we’ll kick off the week of November 6th.”

4. Solve problems before permits get pulled

The worst time to discover a $15,000 utility connection requirement is after you’ve pulled permits and the client thinks they’re locked into a price.

Hill’s proactive approach has saved multiple projects. By engaging outside consultants for utility connections during feasibility and design, SnapADU identifies expensive undergrounding requirements before permits are submitted. That way, they won’t come back to bite them later in the project and lead to a disappointing delay.

Depending on your specific trade, that upfront investigation might look different. Build additions or ADUs? Engage utility consultants. Full remodels? Consider running title and permit history searches before quoting. And most projects could use a structural engineer’s review before committing to a number.

Surprises kill deals. Front-load the bad news when clients still have options.

5. Communicate delays before clients start worrying

Let’s be honest—63% of the public assumes mismanagement leads to construction delays. If you don’t explain what’s happening, clients fill that silence with worst-case assumptions.

“Transparency when communicating delays is key,” Hill says. “Provide reasons for schedule edits and explain attempts made to keep the project on track.”

Clients aren’t construction professionals, and they rarely understand the hidden factors that lead to the complexity of construction timelines. They don’t know about permit office backlogs or material lead times. When you go silent, they assume you’re not managing their job.

Your communication protocol: Update your schedule immediately when you learn about a delay. Explain the reason. Show what you’re doing about it, and provide a revised timeline right away. Regular updates prevent errors and keep everyone aligned.

6. Build your contracts with flexibility

Fixed-price contracts made sense when material costs were predictable. Today, they’re a gamble that can sink your margins.

Hill builds flexibility into contracts to handle delays like tariffs and price shifts. “We implemented price locks with specific timeframes, taking on the risk of labor and material increases, and pegging future price adjustments to the California construction cost index—an objective, neutral third-party metric,” Hill says.

When COVID hit, 68% of contractors had at least one project canceled and 48% saw jobs halted mid-stream. Firms with contract flexibility absorbed those shocks better.

Three clauses to implement:

- Time-limited price locks: Guarantee your materials and labor pricing for 30–60 days from contract signing. After that, you can adjust prices to reflect any new material cost increases you incur.

- Force majeure extensions: Define uncontrollable delays, such as pandemics, natural disasters, or government shutdowns, that might extend timelines without penalty.

- Price adjustment formulas: Peg changes to objective third-party indices.

7. Lower client anxiety with flexible entry points

A bigger threat than project delays is project cancellations caused by anxious clients pulling out before you even start. In 2022, 58% of contractors saw owners cancel or postpone projects.

Hill adapted by “lowering the entry point for clients by disaggregating the upfront feasibility process to provide preliminary budgets with less initial spend and engineering product offerings for a manageable base-level option,” she says.

Offer phased pricing. This varies based on your niche, but may include a feasibility study, design, and construction. Consider tiered packages—think “essential,” with the absolute minimum included, and “premium” packages with bells and whistles.

And increase your conversions with upfront payments. When clients see what monthly financing looks like, fear turns into feasibility. Platforms like Acorn Finance let contractors show real payment options during the estimate, turning an overwhelming $40,000 project into a reasonable $350/month.

That shift from “we can’t afford this” to “we can make this work” keeps deals alive. The homeowner who was planning to wait until next year signs the contract today because the numbers suddenly work.

Your script: “Let’s start with a $2,500 feasibility study that gives you a real budget and timeline. Then you decide if you want to move forward, adjust scope, or wait. No pressure either way.”

Your 30-day action plan

Start with three changes you can implement in the next month.

Week 1: Audit your process. Review all of your projects that have been delayed in the last year. Where did delays happen? Calculate how much schedule slippage cost you in overtime or extended overhead, and identify your most common disruption points so you know where to build buffer.

Weeks 2-3: Pick your system and update contracts. Research project management platforms. The key question: will your subs actually use it? Start with one pilot project. Then, update your contract by adding price adjustment clauses, force majeure language, and time-limited price locks.

Week 4: Create contingency templates. Build timeline templates by project type and size. Include buffer time for permits, materials, and weather. Add 5-15% cost contingency to your estimates, and practice explaining contingencies so it sounds natural.

Stay ahead of what’s coming

Project delays aren’t temporary. Material lead times, permit backlogs, and workforce shortages are built-in industry issues, not just bad luck. But contractors thriving right now haven’t somehow found the magic, perfect circumstances—they created systems that work when conditions don’t cooperate.

The difference between losing a deal and closing it? Proving you can deliver even when market conditions make that difficult. Your next contract isn’t about having the lowest price—it’s about having systems that keep projects on track and clients confident from estimate to completion.